End-to-End Autonomous Planning & Analytics

Unilever – Fortune 100 Global CPG

Managing all their supply chain planning data on a single platform, they achieved real-time visibility & agility for faster decision-making

Inventory Planning involves decisions about the level of inventory, the location, and the mix of products. Inventory is a managed buffer in the supply chain network that protects customer service performance from forecast errors, operational inefficiency, supply variability, and vendor performance. It needs to be tightly coupled with demand and supply planning, as they share common planning parameters and influence each other.

"Even though our main goal as an e-commerce retailer was managing growth after we went live, with Solvoyo our inventory turns improved by 61% while our availability increased by 44% and our sales almost doubled."

You can automatically build multi-stop, multi-modal, and multi-day routes with pickup and delivery time windows, complex tariff structures, operational constraints of the transportation resources, including the dedicated fleet and the drivers, and the hours-of-service regulations. Furthermore, exchange data with your 3PL, your carrier, and your DC ops via any digital interface at any frequency -even real-time. With optimal routing and scheduling capabilities, our platform will reduce your inbound, inter-facility, and outbound transportation costs while increasing delivery performance. With its AI-driven actionable insights, Solvoyo can also help you track your transportation KPIs and fill in the performance leaks in your operations.

On-Time Fulfillment & Availability

Unilever – Fortune 100 Global CPG

Managing all their supply chain planning data on a single platform, they achieved real-time visibility & agility for faster decision-making

Mid-Market CPG in North America

The CPG company used our digital platform with end-to-end planning and analytics capabilities in order to increase its OTIF levels

Hepsiburada – E-Commerce Retailer

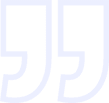

Hepsiburada automated their approach to detect slow moving inventory and optimize price actions to meet budget targets

Not all products are equal in profitability and not all customers have the same priority. Few companies take the time to differentiate their customer service targets and the corresponding inventory investment.

Solvoyo platform has built-in analytics to segment your products and customers based on the following measurable dimensions: Total revenue, total profit, incremental profit, hit rate (market basket analysis), order reliability, forecast error, supply variability, life-cycle state of a product, and life-cycle state of a customer.

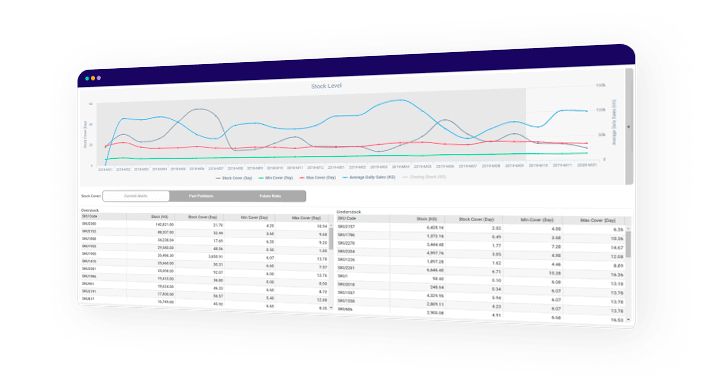

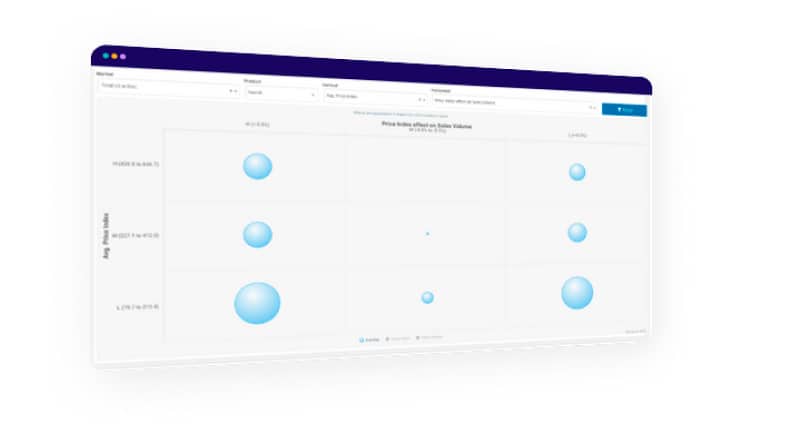

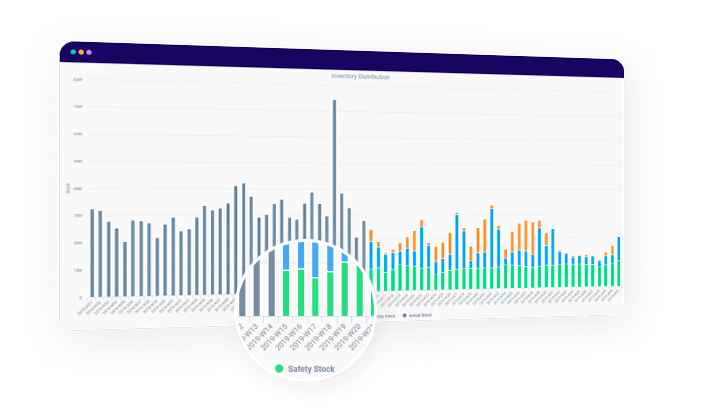

Safety stock protects customer service performance from forecast errors, operational inefficiency, supply variability, and vendor lead-time performance. Therefore, when one of these measures changes for any product, then the safety stock for that product should be dynamically recalculated. However, most companies use a set-it-and-forget-it approach in safety stock targets and fail to adjust to the rapidly changing business conditions. Solvoyo platform provides the ability to measure each of these input parameters or receive them as input from other systems, recalculate the safety stock values automatically and reconcile them based on investment targets across the network. Solvoyo will also adjust stock targets in different echelons of the same network (commonly called Multi-echelon Inventory Optimization), protecting service levels dynamically and, in certain cases, totally autonomously.

Inventory is like cholesterol: there are good and bad kinds and the ratios matter. Inventory loss tree is a way of differentiating all of your physical inventory based on its purpose:

● Safety stock to protect against errors and variability

● Cycle stock to cover demand until the next supply event (e.g., replenishment, procurement, or production)

● Allocated inventory for unshipped orders or planned production

● In-transit inventory that is on the way

● Excess stock that is eating into your cash pile

● Dead inventory that should be cleared out of the storage and the books

● Investment inventory for seasonal builds or opportunity buys

Solvoyo platform has analytic capabilities to give you a real-time high-resolution view of your inventory profile and proactively warn you on stock-outs before the stock-out event and on excess stock before they become excess.

The strategic decision starts with the fundamental one: should I keep inventory or rely on the supplier? If you decide to keep inventory, then there are several tactical and operational decisions you should be aligned on:

● Where in the network should I keep inventory?

● How much safety stock should I keep and when should I reorder?

● How do I balance my investment across finished goods, semi-finished goods, and materials?

Rules of thumb and intuition are still common in making inventory investment decisions. Do not leave money on the table or suffer service failures by ignoring scalable data-driven approaches and machine learning applications for inventory planning. Solvoyo platform gives you a quantitative basis to answer all inventory investment questions with state-of-the-art optimization and advanced AI/ML methods and keep the decisions consistent across time horizons.