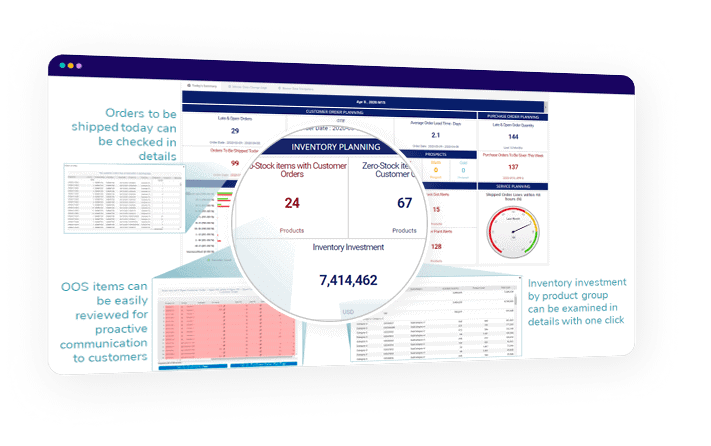

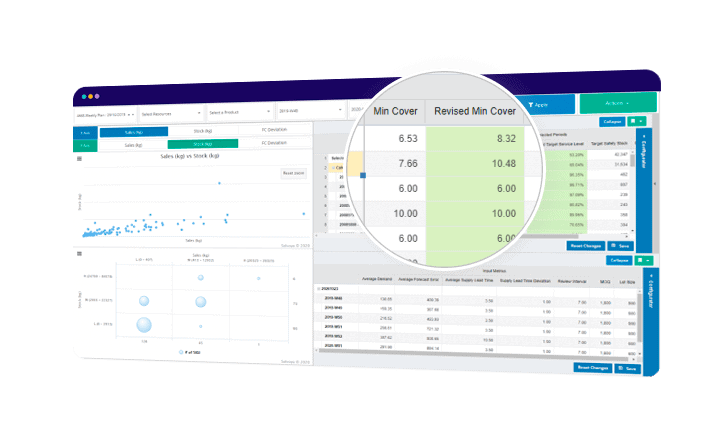

All solutions you need. On a single platform.

No more decision-making in silos!

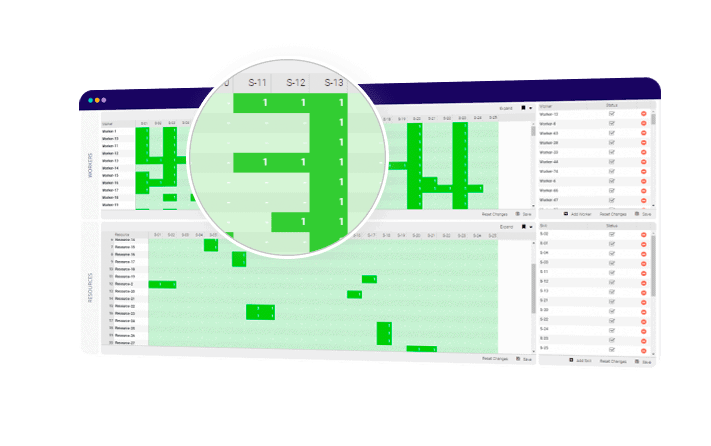

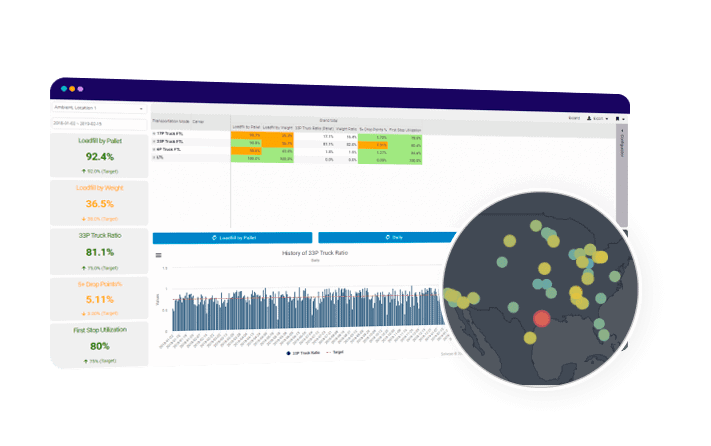

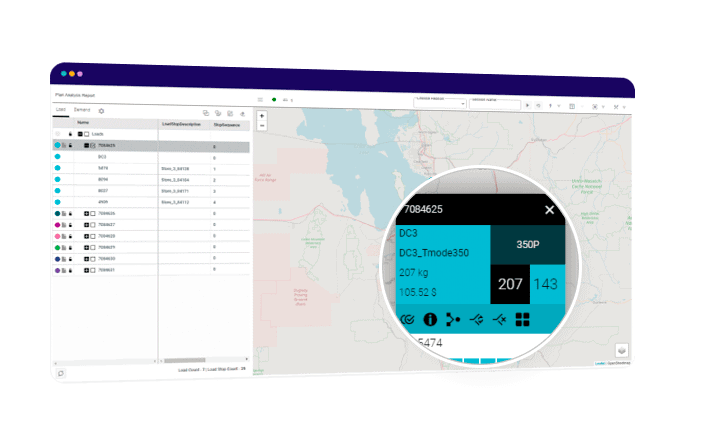

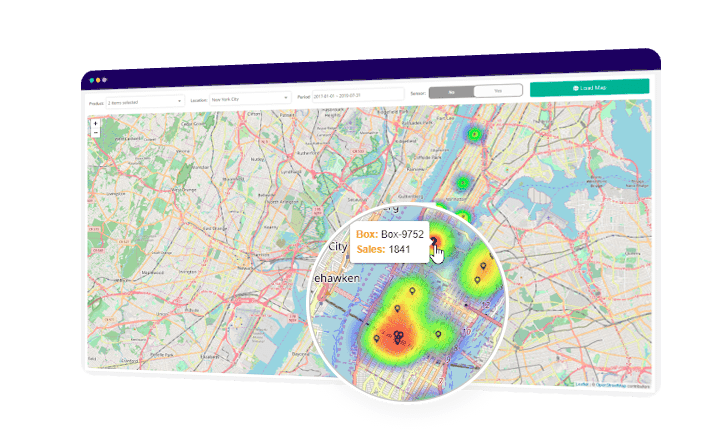

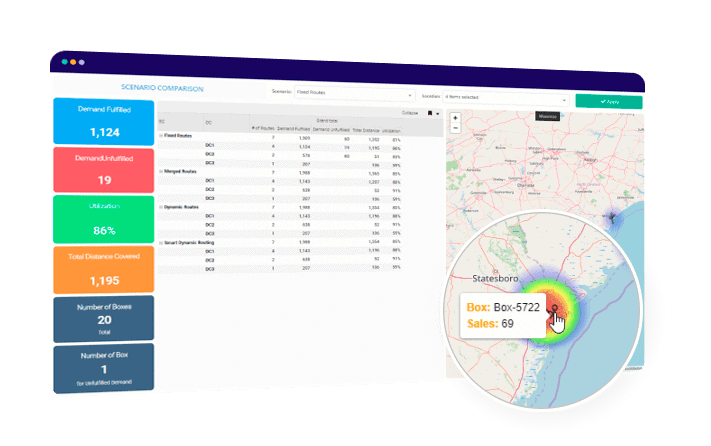

Experience the benefits of a holistic approach and horizontal alignment where you can optimize production, inventory, fulfillment and transportation decisions simultaneously

Solvoyo is an end-to-end planning platform that makes it possible to integrate strategic, tactical, and operational planning decisions