Using AI & ML in Retail Supply Chain Planning

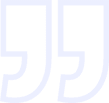

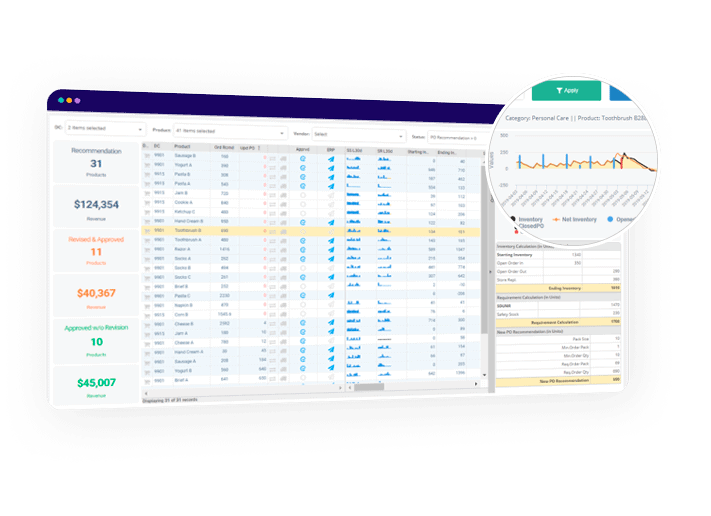

Artificial Intelligence (AI) and Machine Learning (ML) are hot topics being discussed in the retail world. Across the globe, whether they are grocery, mass merchant, or fashion, retailers are looking for ways to make faster and smarter decisions using this technology. Among the leading applications of AI & ML in planning are forecasting and replenishment processes.