As I was growing up, one of my most recurrent dreams (other than being invisible), was to plant a chip in my brain to load every piece of information I found interesting. In fact, when the first Matrix** movie came out, it had everything I dreamed of and more. Too bad I wasn’t a scenarist or looked anything like Keanu Reeves.

Today, the worlds or artificial intelligence (AI) and machine learning in the supply chain are perhaps the closest we will ever get to my dream – at least for my generation. If we cannot put a chip into our brain, how about instead giving machines an ability to think?

How does machine learning work?

Machine Learning grew out of this challenge: to research and create AI. Machine learning is a process of data analysis that allows computers to find insights from huge amounts of data without being explicitly programmed where to look. Since the 90s, machine learning has been recognized as a separate field from AI concentrating more on the solvable problems we face in our day to day life using more statistical-based approaches, than AI, where the focus continues to remain on replicating human-like cognitive thinking in machines.

Interestingly, during this same time, computers and the internet penetrated almost all aspects of our daily lives. Today, we live in a totally digital age where every little bit of information is converted to a digital format and stored as endless ones and zeros. Unlike the previous century’s paper filled libraries and warehouses, this century’s knowledge and archives are vast server farms with almost limitless data storage.

In fact, many companies today have to deal with petabytes of data every day. Everything from customer information, sales or web browsing history to production metrics are all stored in big heaps of data usually on data centers or on the cloud somewhere. Increasingly, these heaps of data collected and stored digitally have picked up a rather fancy moniker “Big Data.”

Today, it is imperative (some might argue even expected) for companies to analyze, summarize and derive meaningful information from all these scrambled pieces of data. Unfortunately, data doesn’t mean information unless you find insights in the form of patterns, trends, connections, or metrics to tell an actionable story. Finding these hidden insights in data has become extremely important for businesses and this is where machine learning comes into play.

Machine learning automates analytical model building by analyzing data and employing techniques such as pattern recognition, clustering, looking for similarities, creating decision trees, and finding and checking rules. As the created models are exposed to the onslaught of new and even continuous streams of data, computers can adapt to fine-tune these models and algorithms to produce ever more reliable and repeatable decisions. Manually, it would be downright impossible to sift through tera or petabytes of data every day.

Recent developments in distributed computing, in-memory databases, decreasing semiconductor prices and the advent of cloud computing make applying complex mathematical models to big data faster, cheaper and more achievable. From autonomous cars to automated medical diagnosis, online recommendation engines, fraud detection, or consumer credit decisions; all are powered by some form of machine learning.

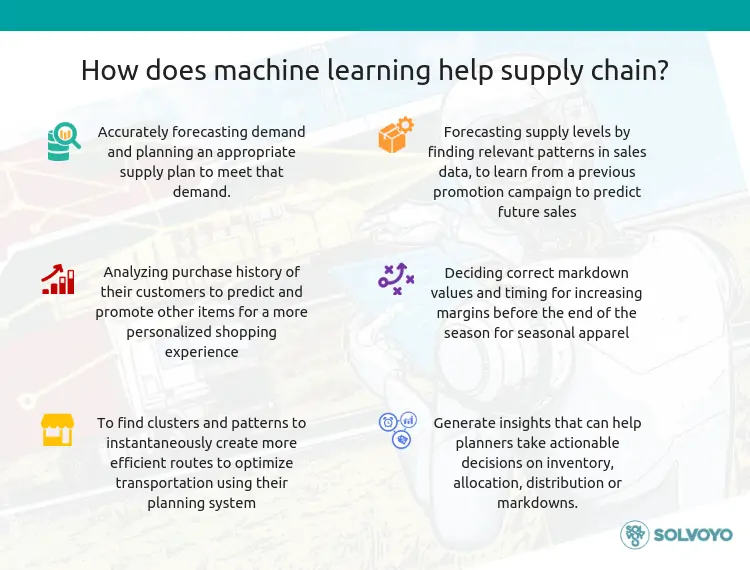

How does machine learning help supply chain?

Supply chain 101 at its core is all about accurately forecasting demand and planning an appropriate supply plan to meet that demand. In today’s hypercompetitive marketplace, supply chain teams have to ensure that you are staying ahead of the competition by accurately forecasting based on historical sales and other market trends, planning the right production or inventory levels based on complex global supply lead times, and minimizing transportation and logistics costs.

The sheer number of data points, volume, and complexity that today’s planners must collect and synchronize to properly run their supply chain operations is growing exponentially every day. Only by combining machine learning to predict, and data mining to discover previously unknown properties in big data, can today’s planner’s gain insights that can help them take actionable decisions on inventory, allocation, distribution or markdowns.

As more data are accumulated every minute of every day, contrary to traditional “set it and forget it” approach, planners today, must start taking advantage of carefully engineered machine learning algorithms adapted to readjust and fine-tune supply chain models to produce more accurate and reliable supply chain plans while eliminating “planner’s bias.” Supply chain teams that employ machine learning to learn from new data each day can close the gap between planning and execution.

Real world examples of machine learning in action in supply chain planning today include Solvoyo’s users:

- Analyzing purchase history of their customers to predict and promote other items for a more personalized shopping experience

- Using machine learning to find clusters and patterns to instantaneously create more efficient routes to optimize transportation using their planning system

- Forecasting supply levels by finding relevant patterns in sales data, to learn from a previous promotion campaign to predict future sales

- Deciding correct markdown values and timing for increasing margins before the end of the season for seasonal apparel

At Solvoyo, we help companies solve demand, inventory, transportation, manufacturing, replenishment, and fulfillment planning in one model across strategic, tactical and operational time horizons, using machine learning to harness the power of big data analytics. Our software and optimization engineers work hand in hand with our industrial engineers to find the best algorithms and models to use in real life supply chain challenges that face our clients. These models and algorithms, which stem from extensive industry experience as well as academic work, are also empowered by machine learning algorithms to increase the accuracy and reliability of our results. Carefully reviewed and selected machine learning algorithms are all part of but not limited to Solvoyo’s markdown optimization, life cycle forecasting, replenishment, and transportation planning solutions.

So go ahead and take the red pill, and awake to where your current planning approaches are failing you and embrace the power of big data and machine learning to transform your supply chain.