When it comes to inbound transportation planning, many manufacturers face the same dilemma: how to ensure raw materials and semi-finished goods flow smoothly from multiple suppliers into production facilities without racking up unnecessary costs or delays. The reality is that traditional approaches to inbound logistics, often based on MRP outputs and manual scheduling, frequently fail to balance supplier calendars, vehicle capacities, and Just-in-Time (JIT) requirements. The result? Half-empty trucks, missed delivery windows, bloated safety stocks, and avoidable logistics costs.

The Inbound Logistics Challenge

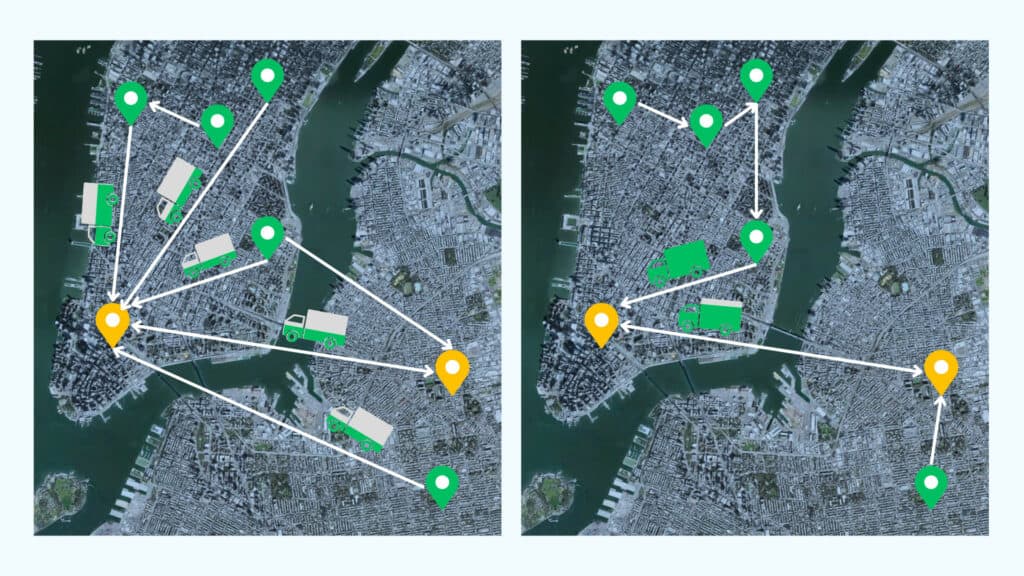

In many industries, inbound shipments follow a ‘milk-run’ model, where vehicles must collect materials from multiple suppliers before heading to the plant.

On paper, it’s efficient. In practice, it’s riddled with logistical challenges and constraints that make execution complex:

- Supplier calendars and shift patterns mean pickups can’t happen whenever you want.

- Vehicle compatibility rules (trucks vs. trailers, urban restrictions, high-volume lanes) limit what can be dispatched where.

- Material and packaging requirements prohibit mixing product types in the same load, complicating consolidation.

- Strict delivery time windows and JIT inbound logistics commitments demand precise sequencing.

- Minimum stock levels and inventory tracking must be upheld without tipping into excess.

Ignoring these constraints leads to exactly what most supply chain executives dread: excess empty miles, poor fleet utilization, delivery delays, and ultimately higher costs with lower service reliability.

The Digital Backbone of Inbound Transportation Planning

At the heart of this transformation is a digital planning backbone that integrates seamlessly with ERP, TMS, and WMS systems. Gartner highlights inbound logistics planning as a critical area where digitalization drives efficiency and resilience, underscoring the need for advanced tools that replace manual scheduling with data-driven decision-making.

By leveraging real-time telematics, predictive analytics, and AI-driven inbound transportation planning engines, supply chains can move from firefighting to continuous improvement. This is the foundation for effective inbound logistics optimization.

Key enablers include:

- Automated data ingestion from ERP systems, replacing manual Excel uploads.

- Configurable rules and master data management to capture evolving business constraints (e.g., delivery windows, vehicle restrictions).

- Interactive dashboards and KPIs that track utilization, cost, and on-time performance in real time.

- Continuous optimization loops that embed sustained performance gains into daily inbound logistics operations.

Why Inbound Logistics Optimization Is Critical for Supply Chain Efficiency

The way forward lies in orchestrating all these moving parts through advanced inbound logistics optimization and decision automation. Instead of daily plans built in silos, an integrated system considers all constraints at once, balancing fleet utilization, cost, and service commitments. This is where optimization modeling becomes a game-changer.

By mathematically representing real-world logistics constraints and objectives, an optimization model transforms inbound transportation planning from guesswork into a structured, data-driven decision-making process.

Benefits of Inbound Logistics Optimization Models

Holistic Constraint Management: Optimization models can account for dozens of rules simultaneously, ensuring that the chosen solution is both feasible and cost-effective.

Scenario Planning and Agility: With optimization, planners can evaluate multiple “what-if” scenarios. Whether the objective shifts from minimizing cost to maximizing service or adapting to new regulatory rules, the model adjusts quickly, something manual planning cannot do at scale.

Quantifiable Gains: By improving fleet utilization, consolidating loads more effectively, and reducing delivery variability, companies see measurable benefits: lower fuel costs, fewer trucks needed, and higher service reliability.

Key Constraints in Inbound Logistics Optimization

General Planning Constraints

Optimization Goal: While the default objective is serving demand, models can be reconfigured to prioritize profitability, revenue growth, or service-level improvements.

Delivery Wait-Time: Plans must respect maximum allowable wait times for each delivery, ensuring timely and compliant service.

Product Categorization: Deliveries grouped by product category simplify handling and compliance, but optimization allows consolidation where possible.

Category Splitting: By intelligently splitting product categories across vehicles, models maximize truck utilization without compromising service.

Demand Zone Constraints

Permitted Vehicle Types: Certain zones may only allow trucks or trailers, or mandate specific vehicle types for high-volume deliveries. Optimization respects these rules while still minimizing costs.

Delivery Time Windows: Strict pickup and drop-off windows are non-negotiable in many zones. An optimization model ensures that schedules align with these operational or regulatory windows.

Delivery Constraints

Package and Material Group Compatibility: Models ensure that incompatible products are not loaded together, while still consolidating loads where allowed to reduce trips.

Vehicle Constraints

Stop Restrictions: Some vehicles may be limited to a certain number of stops, impacting routing efficiency. Models factor this in when designing tours.

Cost and Fuel Efficiency: Optimization includes per-kilometer costs, surcharges (tolls, bridges, stops), and fuel consumption differences between loaded and empty states. This ensures that true costs are minimized, not just distances.

Product Constraints

Volume and Loadability: Effective loadability varies by vehicle type and product shape. Optimization accounts for these variances to ensure realistic and efficient vehicle loading.

The Strategic Payoff

When supply chain executives invest in inbound logistics optimization, the results go beyond cost reduction:

- Improved Fleet Utilization: Fewer trucks doing more work, with lower empty miles.

- Regulatory Compliance: No surprises at urban gates or restricted delivery zones.

- Better Service Levels: On-time, in-full deliveries aligned with JIT needs.

- Sustainability Gains: Fewer kilometers traveled and reduced CO₂ emissions.

Optimization modeling allows organizations to balance service reliability, cost efficiency, and sustainability, turning inbound logistics from a daily firefight into a strategic advantage.

Why This Matters Now

For supply chain executives, the challenge isn’t just moving trucks, it’s balancing resilience, cost-efficiency, and sustainability in a world where every delay or empty run has a ripple effect across the value chain. Inbound logistics optimization reduces waste, improves service, and strengthens the bottom line.

Inbound transportation planning doesn’t need to be a daily firefight. With the right digital tools and optimization strategies, inbound logistics can become a source of competitive advantage.

Inbound Logistics and Transportation Planning FAQ

Inbound logistics optimization is the process of planning and executing the movement of raw materials and goods from suppliers to production facilities in the most efficient way possible. By using digital tools, optimization models, and real-time data, companies can reduce costs, improve fleet utilization, and ensure on-time deliveries.

Optimization ensures that trucks are fully loaded, routes are efficient, and delivery schedules align with supplier calendars and JIT requirements. This reduces empty miles, maximizes the use of available capacity, and lowers overall transportation costs.

Modern inbound transportation planning software enables automated data integration, real-time visibility, and advanced optimization. Companies benefit from fewer trucks on the road, lower fuel costs, better service reliability, and improved sustainability through reduced CO₂ emissions.

Solvoyo’s AI-powered supply chain planning platform brings together inbound transportation planning, fleet optimization, and decision automation in one integrated solution. By modeling every constraint, automating repetitive tasks, and enabling real-time scenario planning, Solvoyo helps companies maximize fleet utilization, cut costs, and improve service reliability, all while reducing environmental impact.

Talk to our experts to see how Solvoyo can transform your inbound logistics operations.