Short planning cycles, unpredictable shoppers, crowded promos—it’s a lot. The good news is you don’t have to plan in the dark. Demand sensing helps you pick up early signals and adjust supply chain plans in real time to respond to the market dynamics.

What Is Demand Sensing?

Demand sensing is the practice of using real-time and near-real-time indicators such as POS, inventory movements, prices, promotions, weather, web traffic, and more to improve short-term demand forecasts and align supply decisions more quickly. Think of it as closing the gap between what just happened and what will happen next, usually over the next few days to a few weeks.

Demand Sensing vs. Demand Forecasting

Traditional demand forecasting builds a statistically sound baseline using history and causal factors. It’s great for medium- to long-term horizons. Demand sensing focuses on the short term, brings in fresh signals continuously, and updates the plan quickly so you can react to step-changes like a surprise heatwave or a viral social post. In short, forecasting sets the trajectory; demand sensing keeps you on the right line when conditions change.

Applications in CPG and Retail

For CPG manufacturers, demand sensing is about seeing beyond wholesale orders to understand true consumer demand. This includes the integrating data such as retailer POS and inventory levels, EDI orders, and trade-promo calendars. This will allow for predicting short-term sales surges or risks. These signals enable manufacturers to fine-tune production sequencing, deploy the right product mix to priority DCs, and adjust order commitments before service levels slip.

For retailers, demand sensing happens at the store-SKU and omnichannel level. Fresh POS data, promotion details, price changes, and online traffic trends reveal where demand is surging or stalling. This allows for daily replenishment adjustment, micro-allocations across stores and online fulfillment centers, smarter promotional buffers, and targeted markdown strategies when needed.

Both sectors rely on external factors like hyperlocal weather, especially for sensitive categories. Advanced planning tools can automatically take these variables into account, ensuring production schedules and inventory deployments adjust with what shoppers are actually buying.

Independent research shows that AI-enabled demand sensing can reduce short-term forecasting errors by 20–50%, cutting lost sales and inventory costs in the process.

Data Integration for Demand Sensing

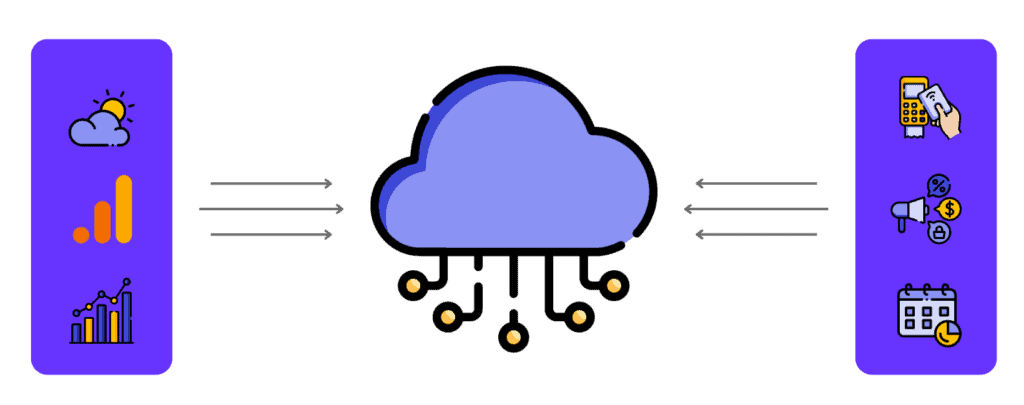

The best platforms blend internal, retailer, and external signals:

- Internal: orders, shipments, on-hand and in-transit inventory, price changes, assortment, and planned promotions.

- Retailer: POS by store and SKU, network inventory, and retailer campaign calendars.

- External: weather forecasts and anomalies, competitor actions, local events, macro indicators, web and app traffic, search trends, and social sentiment.

High performers don’t just collect these; they reconcile them to the short-term planning horizon and refresh daily.

How Demand Sensing Works in Practice

Demand sensing solutions usually have three components, working together like a radar system for your supply chain. Just as a radar system constantly scans the environment for incoming objects, demand sensing continuously monitors your market for subtle signals of changing demand. The three main components are:

- Data ingestion and quality: Connect to POS feeds, ERP, pricing, promo calendars, and third-party data such as weather. Validate and standardize so the signals are comparable.

- Feature engineering and modeling: Transform raw signals into usable features, promo flags and depth, weather deltas vs. seasonal norms, halo and cannibalization indicators, and stockout corrections, then apply ML models suited for short windows.

- Continuous learning: Reconcile short-term signals with the baseline plan and re-optimize frequently. Make updates visible to replenishment and allocation so actions follow insight.

The Solvoyo Take: From Sensed Signal to Action

Many teams stop at insight. Solvoyo goes further—connecting sensed demand to automated recommendations across replenishment, allocation, and procurement.

- Weather-aware forecasting: Solvoyo natively incorporates weather data and other external drivers alongside internal history to lift short-term accuracy, then feeds the results into replenishment planning to keep shelves ready.

- Promotion-aware scenarios: Plan baseline vs. promo-lift forecasts, test depth and duration, and reflect those changes in replenishment targets automatically so the DC and the stores are in sync.

- Demand sensing at SKU-store level: Translate website traffic, click-through, and in-store signals into near-term forecast updates and immediate actions.

- One platform for visibility to action: A digital twin brings demand, inventory, and supply into one place so exceptions, what-ifs, and prescriptive moves sit side by side.

See how Solvoyo unifies demand, inventory, and replenishment on one platform.

Demand Sensing FAQ

No. Manufacturers benefit by sensing downstream POS and retailer inventory to stabilize production and deployment.

Most teams begin with 2–8 weeks, then expand once data pipelines mature.

You need consistent POS and promo calendars, basic out-of-stock correction, and a reliable weather feed. Data gets cleaner once the process runs every day.

No. It reduces routine overrides and highlights exceptions where human judgment adds the most value.